BJ45直流式夹套保温截止阀

川沪首页 >> 截止阀 >> BJ45直流式夹套保温截止阀

一、BJ45直流式夹套保温截止阀 产品概述

|

上海川沪阀门有限公司专业生产的Y型保温截止阀,适用于易结晶流体,由于外面加了一层保温夹套,保温层一般通入蒸汽或者导热油,可以有效保证阀门内部的流体不会结晶。而Y型的结构,可以大限度降低阀芯对流体的阻力,保证介质流量不会因为保温截止阀而损耗。保温截止阀的设计制造标准如下: 1、设计制造按GB12234-89 GB12234-89 |

二、BJ45直流式夹套保温截止阀 产品型号和图片

|

BJ45直流式夹套保温截止阀 |

三、BJ45直流式夹套保温截止阀 技术规范

| 零件名称LTEM | ZG1CR18NI9TI系列 | ZGOOCR18NI10系列 | ZG1Cr18Ni12MO2Ti系列 | ZGOOCR17NI14MO2系列 |

| 阀体/阀盖世BODY/CAP | ZG1CR18NI9TI | ZGOOCR18NI10 | ZG1Cr18Ni12MO2Ti | ZGOOCR17NI14MO2 |

| 闸板WEDGE | ZG1CR18NI9TI | ZGOOCR18NI10 | ZG1Cr18Ni12MO2Ti | ZGOOCR17NI14MO2 |

| 阀杆STEM | 1CR18NI9TI | 00cr18ni10 | 1CR18NI12MOTI | OOCR17NI14MO? |

| 填料PACKING | PTFE纺织 | PTFE纺织 | PTFE纺织 | PTFE纺织 |

| 垫片GASKET | 304L+PTFE | 304L+PTFE | 316L+PTFE | 316L+PTFE |

| 压盖GLAND FLANGE | ZG1CR18NI9TI | ZG00CR18ni10 | ZG1Cr18Ni12MO2Ti | ZGOOCR17NI14MO2 |

| 填料压环 STUFFING RING |

1CR18NI9TI | 00CR18NI10 | 1Cr18NI12MOTI | OOCR17NI14MO?? |

| 螺栓BOLT | 1cr17ni2 | 1CR17NI2 | 1Cr17NI2 | 1Cr17Ni2 |

| 螺母NUT | 1cr18ni9ti | 1CR18NI9TI | 1Cr18NI9ti | 1Cr18NI9ti |

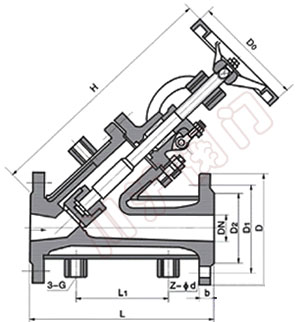

四、BJ45直流式夹套保温截止阀 外形尺寸图

|

BJ45直流式夹套保温截止阀 外形尺寸图 |

五、BJ45直流式夹套保温截止阀 外形连接尺寸

| 公称通径 | 尺寸 | ||||||||

| L | D | D1 | D2 | b | 3-G | Z-d | H | D0 | |

| BJ45W | |||||||||

| 15 | 130 | 105 | 75 | 55 | 14 | 3/8 | 4-14 | 175 | 180 |

| 20 | 150 | 115 | 85 | 68 | 14 | 3/8 | 4-14 | 185 | 180 |

| 25 | 160 | 135 | 100 | 78 | 16 | 3/8 | 4-18 | 210 | 200 |

| 32 | 180 | 145 | 110 | 85 | 16 | 3/8 | 4-18 | 350 | 200 |

| 40 | 200 | 160 | 125 | 100 | 16 | 3/8 | 4-18 | 360 | 200 |

| 50 | 250 | 180 | 145 | 120 | 18 | 1/2 | 4-18 | 380 | 240 |

| 65 | 265 | 195 | 160 | 135 | 20 | 1/2 | 8-18 | 440 | 240 |

| 80 | 280 | 215 | 180 | 155 | 20 | 1/2 | 8-18 | 510 | 280 |

| 100 | 300 | 245 | 210 | 185 | 22 | 1/2 | 8-18 | 620 | 320 |

| 125 | 325 | 280 | 240 | 210 | 24 | 1/2 | 8-23 | 680 | 360 |

| 150 | 350 | 335 | 295 | 265 | 26 | 1/2 | 12-23 | 818 | 360 |

| 200 | 400 | 405 | 355 | 320 | 30 | 1/2 | 12-25 | 1200 | 400 |

| 250 | 450 | 460 | 410 | 375 | 30 | 1/2 | 12-25 | 1450 | 450 |

| 300 | 500 | 520 | 470 | 435 | 34 | 1/2 | 16-25 | 1600 | 500 |

|

|

调节阀系列

调节阀系列